Partial dosages of Caesalpinia Spinosa ash and cement fiber in asphalt mixtures for flexible pavements

DOI:

https://doi.org/10.51372/gacetatecnica262.3Keywords:

Caesalpinia Spinosa ash, cement fibers, modified asphalt mixturesAbstract

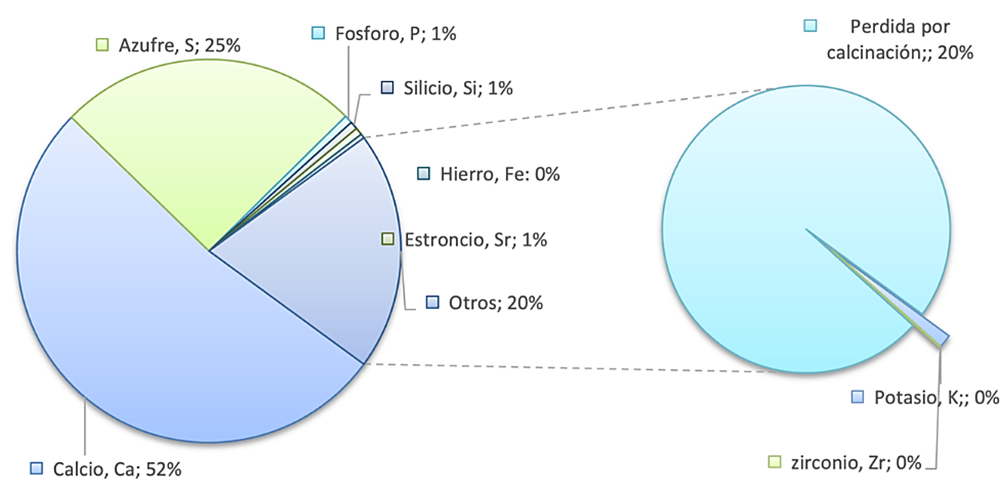

This experimental study evaluates the influence of the partial addition of Caesalpinia Spinosa ash (CS) or Tara ash, and Fiber Cement (FC) in asphalt mixtures for flexible pavements. Mineral filler replacement percentages of 1,0%, 1.5% and 2,5% were analyzed using the Marshall and Lottman tests, with the aim of determining their effect on stability, creep and resistance to moisture. This mixture improves its properties, therefore. tend to be applicable to roads. A total of 51 briquettes of selected asphalt mixture were manufactured. The distribution of specimens was organized into two groups: the first composed of 27 specimens for the Marshall test and the second by 24 for the Lottman test. From the pattern set (0% modification), 18 briquettes were prepared for the Marshall test, and 6 were intended for the and Lottman tests. In the case of the mixtures modified with additives at concentrations of 1,0%, 1,5% and 2,5%, 3 and 6 specimens were prepared for each test, respectively. The results of the Marshall test indicate a decrease in stability compared to the standard sample (1289,9 kg), with values of 1271,9 kg, 1198 kg, and 1256 kg for 1.0%, 1,5%, and 2,5% CS+FC, respectively. Creep values ranged from 2,91 mm for the standard sample to 3.5 mm, 3.26 mm, 3.08 mm, and 2,93 mm, depending on the addition percentage. Finally, the indirect tensile strength test (TSR) showed values of 82,7%, 79,6%, 81,2%, and 76,7%.

Downloads

References

O. Oyedepo, E. Olukami, A. Alalade, A. Amuko, G. Oluwadare y O. Oyanda, “Evaluation of the Strength Properties of Asphalt Concrete using Natural Fibers as Reinforcing Additives” Nigerian Journal of technological development, vol. 18, nº 4, pp. 302-3011, 2021.

K. Kikut, A. Elizondo y A. Baldi, “Beneficio del uso de cal hidratada en mezclas asfálticas” Infraestructura Vial, vol. 22, nº 39, p. 1219, 2020

M. A. Haddad y T. S. Khedaymi, “Moisture resistance of olive husk ash modified asphalt mixtures” Annales de Chimie- Science des Materiaux, vol. 47, nº 3, pp. 141-149, 2023

O. Aladegboye, D. Oguntayo, A. Lhekwaba, T. E. Daniel, P. C. Chiadighikaobi y P. Ng¨andu, “Evaluation of volumetric properties of cassava peel ash modified asphalt mixtures” Civil Engineering Journal, vol. 8, nº 10, pp. 2110-2124, 2022

C. Chaira y T. Bambang, “Performance evaluation of asphalt concrete wearing coarse with a mixture of coal fly ash brick powder as filler” AIP conference Proceeding, vol. 2629, 2023

S. Min, J. Shou, W. Haibo, Z. Jun, Y. Yungfu, Z. Ye y X. Qingpeng, “Preparation scheme optimization of thermosetting polyurethane modified asphalt” Polymers, vol. 15, nº 10, 2023

A. Padilla Rodriguez, “Análisis de la resistencia a las deformaciones plásticas de mezclas bituminosas densas de la normativa mexicana mediante el ensayo de pista”, Trabajo de Grado, Universitat Politecnica de Catalunya, España, 2004.

Association of Asphalt Paving Technologists, “Marshall Procedures for Design and Quality Control of Asphalt Mixtures” Asphalt Paving Technology: Proceedings, vol. 54, Association of Asphalt Paving Technologists Technical Sessions, 11-13. San Antonio, TX. pp. 265-284, 1985

R. P. Lottman, “The moisture mechanism that causes asphalt stripping in asphaltic pavement mixtures” 1971

ASPHALT WAQTC, “Sampling of bituminous paving mixtures” Fop for AASHTO T 168, IDAHO FOP AASHTO T 168 (10), T168_short_10.docx Asphalt 11-1 Pub, Disponible en: https://apps.itd.idaho.gov/apps/manuals/QA/Archive/files/2013Jan/2013FILES/files/2013Jan/570/asphalt/t168wpr10.pdf. 2012

ASTM, “Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures” ASTM D2172-05, West Conshohocken, PA, EUA, 2010

ASPHALT WAQTC, “Mechanical analysis of extracted aggregate, fop for AASHTO T30” ASPHALT WAQTC FOP AASHTO T 30 (24), 52_T30_short_24_errata Asphalt 20-1 Pub, 2024

ASTM, “ASTM D6926-20. Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus” West Conshohocken, PA, EUA, 2020

ASTM, “ASTM D6927-15. Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures” West Conshohocken, PA, EUA, 2022

ASTM, “ASTM D420-18, Standard Guide for Site Characterization for Engineering Design and Construction Purposes”, West Conshohocken, PA, EUA, 2018

CP12-025 – MTC, “Manual de Ensayo de Materiales”, Ministerio de Transporte y Comunicaciones, Dirección General de Caminos y Transporte, Perú, 2016

Published

How to Cite

Issue

Section

Copyright (c) 2025 Copyright will be assigned automatically to Víctor Raúl Amao Eslachin, Leopoldo Choque Flores when this is published

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The opinions expressed by the authors do not necessarily reflect the position of the editor of the publication or UCLA. The total or partial reproduction of the texts published here is authorized, provided that the complete source and electronic address of this journal is cited. Authors have the right to use their articles for any purpose as long as it is done nonprofit. The authors can post on the internet or any other media the final approved version of their work.

.png)