Influence of recycled rubber as fine aggregate on the compressive and abrasion resistance of concrete paving blocks

DOI:

https://doi.org/10.51372/gacetatecnica271.4Keywords:

concrete, paving stones, recycled rubber particles, compressive strengthAbstract

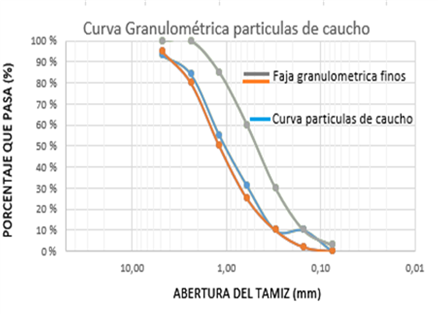

Transportation infrastructure is crucial for economic and social development, especially in countries like Ecuador, where its condition significantly impacts connectivity, the supply chain, and the population's standard of living. This study analyzed the use of recycled rubber particles from end-of-life tires as a partial replacement for fine aggregate in the production of concrete pavers. Mixtures with substitution rates of 3%, 5%, 10%, 12%, and 20% were prepared and evaluated using standardized tests to measure compressive strength and abrasion resistance. The findings indicated a progressive reduction in compressive strength as the amount of rubber increased, yielding values between 38,94 MPa and 27,36 MPa. The mixture with 12% rubber achieved a compressive strength of 36,10 MPa, exceeding the minimum requirement of 35 MPa. During the abrasion test, the paving stones exhibited a chord length of 25 mm, meeting national standards and surpassing the performance of traditional paving stones. Statistical analysis, after removing 13,09% of outliers, confirmed that the data were normally distributed (p = 0,056). This ensures with 95% confidence that a randomly selected paving stone will have a compressive strength between 36,12 MPa ± 2 × 0,301 MPa

Downloads

References

M. Fang, R. Zhou, W. Ke, B. Tian, Y. Zhang, and J. Liu, “Precast system and assembly connection of cement concrete slabs for road pavement: A review,” ScienceDirect, vol. 9, no. 2, pp. 208–222, 2022

R. Agrawal et al., “Utilization of plastic waste in road paver blocks as a construction material,” CivilEng, vol. 4, no. 4, pp. 1071–1082, December 2023

M. A. Peker, “Evaluation of concrete pavers affected by manavgat wildfires,” Journal of Sustainable Construction Materials and Technologies, vol. 6, no. 4, pp. 168–172, December 2021

M. Wojnowska-Heciak, J. Heciak, and A. Kłak, “Concrete paving slabs for comfort of movement of mobility-impaired pedestrians - a survey,” Int J Environ Res Public Health, vol. 19, no. 6, pp. 1–17, March 2022

C. Balegamire, B. Nkuba, and P. Dable, “Production of gold mine tailings based concrete pavers by substitution of natural river sand in misisi, eastern congo,” Clean Eng Technol, vol. 7, pp. 1–7, April 2022

N. A. H. H. Ahmed and A. Thamir Ibraheem, “Sustainable Road paving: Enhancing concrete paver blocks with zeolite-enhanced cement,” Open Engineering, vol. 14, no. 1, pp. 1–12, January 2024

D. V. Cruz et al., “Effect of adding rice husk on the physical and mechanical properties of concrete paving blocks,” Revista Materia, vol. 30, 2025

B. Kiliç and P. Biçer, “Experimentally investigating the usability of waste interlocking concrete paver in the plant-mix base layer,” Journal of the Faculty of Engineering and Architecture of Gazi University, vol. 37, no. 3, pp. 1309–1323, 2022

J. Kim and N. Kim, “Recycling waste paver blocks in the manufacture of new concrete paver blocks and building bricks,” Applied Sciences, vol. 12, no. 21, pp. 1–12, November 2022

U. Asif, M. F. Javed, D. M. Alsekait, D. S. AbdElminaam, and H. Alabduljabbar, “Toward sustainability: Integrating experimental study and data-driven modeling for eco-friendly paver blocks containing plastic waste,” Reviews on Advanced Materials Science, vol. 63, no. 1, pp. 1–22, January 2024

A. Ayyadurai, S. M. Maruthai, and D. Muthu, “Impact of fly ash and banana fiber on mechanical performance of paver block concrete,” Gradjevinar, vol. 76, no. 3, pp. 211–222, 2024

B. Iftikhar et al., “Experimental study on the eco-friendly plastic-sand paver blocks by utilising plastic waste and basalt fibers,” Heliyon, vol. 9, no. 6, June 2023

B. G. Naik, G. Nakkeeran, D. Roy, and G. U. Alaneme, “Investigating the potential of waste glass in paver block production using RSM,” Sci Rep, vol. 14, no. 1, September 2024

M. R. R. Rajan, D. Rajalinggam, K. Narayanan, and S. Ramasamy, “Eco-friendly paver blocks: repurposing plastic waste and foundry sand,” Revista Materia, vol. 30, 2025

R. D. Opeoluwa and D. I. Bolanle, “The effective re-use of foundry sand waste in the production of concrete,” Civil Engineering and Architecture, vol. 12, no. 5, pp. 3426–3440, September 2024

S. Sundaramurthy et al., “Performance evaluation of environmentally sustainable precast cement concrete paver blocks using fly ash and polypropylene fibre,” Sustainability, vol. 14, no. 23, pp. 1–16, December 2022

W. R. A. N. Jayantha and W. K. Mampearachchi, “Use of demolished concrete waste for resurfacing of low volume roads in sri lanka using roller compacted concrete (RCC) technology,” Engineer: Journal of the Institution of Engineers, Sri Lanka, vol. 54, pp. 39–47, September 2021

G. U. Kiran, G. Nakkeeran, D. Roy, and G. U. Alaneme, “Optimization and prediction of paver block properties with ceramic waste as fine aggregate using response surface methodology,” Sci Rep, vol. 14, no. 1, December. 2024

K. Castañeda, O. Sánchez, R. F. Herrera, and G. Mejía, “Highway planning trends: a bibliometric analysis,” Sustainability, vol. 14, pp. 1–33, May 2022

E. C. T. Nogueira and E. F. T. de Oliveira, “Uma aplicação de acoplamento bibliográfico de autores aos estudos métricos da informação no Brasil,” Em Questão, vol. 29, pp. 1–21, May 2023

R. Habib and M. T. Afzal, “Paper recommendation using citation proximity in bibliographic coupling,” Turkish Journal of Electrical Engineering and Computer Sciences, vol. 25, no. 4, pp. 2708–2718, January 2017

R. Sekhar, D. Sharma, and P. Shah, “State of the art in metal matrix composites research: A bibliometric analysis,” Applied System Innovation, vol. 4, no. 4, pp. 1–43, December. 2021

NTE INEN 862, “Áridos para hormigón. Determinación del contenido total de humedad” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2011

ASTM C33/C33M-18, “Standard specification for concrete aggregates”, West Conshohocken, PA, USA, 2018

INEN 490-5, “Tipos de cemento” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2011

INEN 2617, “Hormigón de cemento hidráulico. Agua para mezcla. Requisitos” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2012

ASTM C1602/C1602M-22, “Standard specification for mixing water used in the production of hydraulic cement concrete”, West Conshohocken, PA, USA, 2022

INEN 696, “Áridos. Determinación del análisis granulométrico en los áridos gruesos y finos” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2011

ASTM C136/C136M-19, “Standard test method for sieve analysis of fine and coarse aggregates”, West Conshohocken, PA, USA, 2019

INEN 860, “Áridos. Determinación del valor de la degradación del árido grueso de partículas menores a 37,5 mm mediante el uso de la máquina de Los Ángeles” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2011

ASTM C131/C131M-20, “Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Ángeles machine”, West Conshohocken, PA, USA, 2020

INEN 856 “Áridos. Determinación de la densidad, densidad relativa (gravedad específica) y absorción del árido fino” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2010

INEN 857, “Áridos. Determinación de la densidad, densidad relativa (gravedad específica) y absorción del árido grueso” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2010

ASTM C127-15, “Standard test method for relative density (specific gravity) and absorption of coarse aggregate”, West Conshohocken, PA, USA, 2015

ASTM C128-15, “Standard test method for relative density (specific gravity) and absorption of fine aggregate”, West Conshohocken, PA, USA, 2015

INEN 855, “Áridos. Determinación de las impurezas orgánicas en el árido fino para hormigón” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2010

ASTM C40/C40M-20, “Standard test method for organic impurities in fine aggregates for concrete”, West Conshohocken, PA, USA, 2020

ACI 211.1-91, “Standard practice for selecting proportions for normal, heavyweight, and mass concrete” American Concrete Institute, Farmington Hills, MI, USA, 1991

INEN 3124, “Hormigón. Elaboración y curado de especímenes de ensayo en el laboratorio” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2017

ASTM C31/C31M-24, “Standard practice for making and curing concrete test specimens in the field”, West Conshohocken, PA, USA, 2024

INEN 1573, “Hormigón de cemento hidráulico. Determinación de la resistencia a la compresión de especímenes cilíndricos de hormigón de cemento hidráulico” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2010

ASTM C39/C39M-21, “Standard test method for compressive strength of cylindrical concrete specimens”, West Conshohocken, PA, USA, 2021

J. Alnahas et al., “Enhancing the properties of concrete with the incorporation of recycled polypropylene plastic,” Buildings, vol. 15, no. 7, pp. 1–22, April 2025

INEN 3040, “Adoquines de hormigón. Requisitos y métodos de ensayo” Instituto Ecuatoriano de Normalización, Quito, Ecuador, 2016

Rai, Z. Ahmad, M. J. Hasan, and J. M. Kim, “A novel pipeline leak detection technique based on acoustic emission features and two-sample kolmogorov–smirnov test,” Sensors, vol. 21, no. 24, pp. 1–13, December 2021

E. Eker, “Development of random walks strategy based dandelion optimizer and its application to engineering design problems,” IEEE Access, vol. 13, pp. 56547–56575, April 2025

O. S. Ohunakin, E. U. Henry, O. J. Matthew, V. U. Ezekiel, D. S. Adelekan, and A. T. Oyeniran, “Conditional monitoring and fault detection of wind turbines based on Kolmogorov–Smirnov non-parametric test,” Energy Reports, vol. 11, pp. 2577–2591, February 2024

S. Beltozar-Clemente, O. Iparraguirre-Villanueva, J. Zapata-Paulini, and M. Cabanillas-Carbonell, “Changing mathematical paradigms at the university level: feedback from a flipped classroom at a peruvian university,” International Journal of Engineering Pedagogy, vol. 13, no. 6, pp. 76–89, 2023

A. Daikh, Y. M. Arbi, M. Bentahar, and N. Mahmoudi, “Design and performance of a manual extruder for recycled plastic-brick composite pavers,” Military Technical Courier/Vojnotehnicki glasnik, vol. 72, no. 4, pp. 1802–1831, October. 2024

A. Purnell, D. Sapsford, S. L. Evans, C. Kooij, and P. Wauters, “Application of the Fuller–Thompson equation in sinter blend design to increase sinter productivity,” Ironmaking & Steelmaking: Processes, Products and Applications, vol. 51, no. 6, pp. 556–570, August. 2024

H. Wiyanto et al., “Determining concrete structure condition rating based on concrete compressive strength,” Buildings, vol. 12, no. 6, pp. 1–13, June 2022

INEN 1485, “Adoquines. Determinación de la resistencia a la compresión” Instituto Ecuatoriano de Normalización, Quito, Ecuador 1987

Published

How to Cite

Issue

Section

Copyright (c) 2026 Byron Iván Altamirano León, Carlos Alberto Romero Romero, Milton Javier Caiza Escobar, Rosa Angelica Chipugsi Carua, Joseph Fritzner

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The opinions expressed by the authors do not necessarily reflect the position of the editor of the publication or UCLA. The total or partial reproduction of the texts published here is authorized, provided that the complete source and electronic address of this journal is cited. Authors have the right to use their articles for any purpose as long as it is done nonprofit. The authors can post on the internet or any other media the final approved version of their work.

.png)