Analysis of the technical efficiency of the maintenance of a natural gas compressor plant using Data Envelopment Analysis (DEA)

Keywords:

Technical efficiency, DEA, Maintenance, Productivity, Natural gas compressor plantAbstract

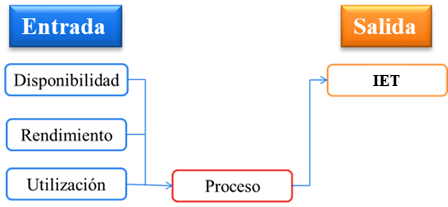

The purpose was to evaluate the technical efficiency of the maintenance performed in a natural gas compressor plant owned by PDVSA Gas, located in the state of Monagas, Venezuela, during the years 2011 to 2022. The DEA method was used based on technical modifications to the OEE indicator and the impact of the maintenance actions implemented was determined. Initially, the years were assigned as DM, obtaining during the period 2011-2016 acceptable efficiencies (> 80 %), while during the period 2017 - 2022 the efficiencies decreased over time, which was considered as the critical period. A second phase for these years, the four motor-compressor units were considered as DMU, so during 2017-2019 the best efficiency (> 80 %) was presented by the unit called K1040, the other units presented a behavior not in accordance with the expected. In the period 2020-2022 there was evidence of a decrease in efficiency below 80 % in 66.7 % of the units. It is concluded that the application of the DEA method based on the modification of the OEE indicator to measure the technical efficiency of maintenance actions can be considered as a tool that presents results in accordance with the reality under study.

Downloads

References

Muchiri, P.; Pintelon, L.; Gelders, L., y Martin, H. (2011) "Development of maintenance function performance measurement framework and indicators". International Journal of Production Economics, vol. 131, no. 1, pp. 295-302. https://www.sciencedirect.com/science/article/abs/pii/S0925527310001726

Ran, Y.; Zhou, X.; Lin, P.; Wen, Y. y Deng, R. (2019) "A survey of predictive maintenance: Systems, purposes and approaches". IEEE Communications Surveys & Tutorials, vol. XX, no. XX, pp. 1-35. https://www.researchgate.net/publication/337971929_A_Survey_of_Predictive_Maintenance_Systems_Purposes_and_Approaches

Agergaard, J. K.; Sigsgaard, K. V.; Mortensen, N. H.; Ge, J.; Hansen, K. B. y Khalid, W. (2021) "Standardising maintenance jobs to improve grouping decision making". Proceedings of the Design Society, vol. 1, pp. 2701-2710. https://orbit.dtu.dk/files/255815412/standardising_maintenance_jobs_to_improve_grouping_decision_making.pdf

Motaghare, O.; Pillai, A. S. y Ramachandran, K. I. (2018) "Predictive maintenance architecture" in 2018 IEEE International Conference on Computational Intelligence and Computing Research (ICCIC). https://www.researchgate.net/publication/334888263_Predictive_Maintenance_Architecture

Tarar, M. A. (2014) "Study reliability centered maintenance (RCM) of rotating equipment through predictive maintenance" in 2nd International Conference on Research in Science, Engineering and Technology (ICRSET’2014), Dubai. https://iieng.org/images/proceedings_pdf/4824E0314595.pdf

Yi, W. y Chan, A. P. (2014) "Critical review of labor productivity research in construction journals" Journal of Management in Engineering, vol. 30, no. 2, pp. 214-225. https://ascelibrary.org/doi/abs/10.1061/%28ASCE%29ME.1943-5479.0000194

Hwang, B. G.; Zhu, L. y Tzu Ming, J. T. (2017) "Factors affecting productivity in green building construction projects: The case of Singapore" Journal of Management in Engineering, vol. 33, no. 3, p. 04016052, 2017. https://www.researchgate.net/publication/308522362_Factors_Affecting_Productivity_in_Green_Building_Construction_Projects_The_Case_of_Singapore

Kaplan, R. y Cooper, R. (1998) "Cost and effect: using integrated systems to drive profitability and performance", Boston: Harvard Business School Press.

Sumanth, D. (1998) "Total Productivity Management. A systemic and quantitative approach to compete in Quality, Price and Time", CRC Press Company. New York

Hill, T. (1993) "Manufacturing Strategy: The Strategic Management of the Manufacturing Function", London: Open University/Macmillan.

Prokopenko, J. (1989) La Gestión de la Productividad. Manual Práctico, Ginebra: Organización Internacional del Trabajo.

Mora, L. (2009) Mantenimiento. Planeación, Ejecución y Control, Ciudad de México: Alfaomega.

O’Brien, M. (2015) "TPM & OEE" LBS Partners, Ireland. https://www.lbspartners.ie/wp-content/uploads/2018/12/TPM-OEE-EBook_LBSPartners.pdf

Anusha, C. H. y Umasankar, V. (2020) "Performance prediction through OEE-model" International Journal of Industrial Engineering and Management, vol. 11, no. 2, pp. 93-103. https://ijiemjournal.uns.ac.rs/images/journal/volume11/IJIEM_256.pdf

Ádám, B. A. y Sebestyén, Z. (2023) "Comparison of OEE-based manufacturing productivity metrics" in Creative Construction Conference 2023, Keszthely, Hungary. https://repozitorium.omikk.bme.hu/bitstreams/162797a0-f2a8-4202-b41b-0a77f8695779/download

Pérez-Cedeño, R. O. y Vásquez-Stanescu, C. L. (2022) "Relación entre el consumo energético y las emisiones de CO2 con el índice de desarrollo humano en países americanos: un análisis de eficiencia usando DEA" Publicaciones en Ciencias y Tecnología, vol. 16, no. 1, pp. 3-15. https://revistas.uclave.org/index.php/pcyt/article/view/3942

Charles, V.; Aparicio, J. y Zhu, J. (2019) "The curse of dimensionality of decision-making units: A simple approach to increase the discriminatory power of data envelopment analysis" European Journal of Operational Research, vol. 279, no. 3, pp. 929-940.

Gong, Y.; Liu, J. y Zhu, J. (2019) "When to increase firms’ sustainable operations for efficiency? A data envelopment analysis in the retailing industry," European Journal of Operational Research, vol. 277, no. 3, pp. 1010-1026. https://www.sciencedirect.com/science/article/abs/pii/S0377221719305168

Osorio-Oviedo, A. A. (2019) "Evaluación de la Eficiencia del Crecimiento de la Industria de Cereales en América Aplicando Análisis Envolvente de Datos". Publicaciones en Ciencias y Tecnología, vol. 13, no. 1, pp. 41-50. https://revistas.uclave.org/index.php/pcyt/article/view/2146

Tayal, A.; Solanki, A. y Singh, S. P. (2020) "Integrated frame work for identifying sustainable manufacturing layouts based on big data, machine learning, meta-heuristic and data envelopment analysis" Sustainable Cities and Society, vol. 62, p. 102383. https://www.sciencedirect.com/science/article/abs/pii/S2210670720306041

Mirmozaffari, M.; Shadkam, E.; Khalili, S. M. y Yazdani, M. (2021) "Developing a novel integrated generalised data envelopment analysis (DEA) to evaluate hospitals providing stroke care services" Bioengineering, vol. 8, no. 12, p. 207. https://www.mdpi.com/2306-5354/8/12/207

Fotova Čiković, K. y Lozić, J. (2022) "Application of Data Envelopment Analysis (DEA) in information and communication technologies" Tehnički glasnik, vol. 16, no. 1, pp. 129-134. https://doaj.org/article/d283f49d860a40298ed17733bfe03c17#:~:text=Data%20Envelopment%20Analysis%20(DEA)%20is,variables%20to%20multiple%20output%20variables.

Akram, M.; Shahzadi, S.; Shah, S. M. U. y Allahviranloo, T. (2023) "A fully Fermatean fuzzy multi-objective transportation model using an extended DEA technique" Granular Computing, pp. 1-32. https://link.springer.com/article/10.1007/s41066-023-00399-6

Winatie, A.; Maharani, B. P. y Rimawan, E. (2018) "Productivity Analysis to increase overall equipment effectiveness (OEE) by implementing total productive maintenance" International Journal of Innovative Science and Research Technology, vol. 3, no. 12, pp. 433-439. https://ijisrt.com/wp-content/uploads/2019/01/IJISRT18DC196.pdf

Yanez, M.; Gómez de la Vega, H. y Valbuena, G. (2004) "Ingeniería de Confiabilidad y Análisis Probabilístico de Riesgo", R2M.

Schuschny, A. R. (2007) "El método DEA y su aplicación al estudio del sector energético y las emisiones de CO2 en América Latina y el Caribe", CEPAL. https://digitallibrary.un.org/record/600891?ln=es&v=pdf

Périco, A. E.; Brandao Santana, N. y Do Nascimento Rebelatto, D. A. (2016) "Estimating the efficiency from Brazilian banks: a bootstrapped Data Envelopment Analysis (DEA)" Production, vol. 26, no. 3, pp. 551-561. https://www.redalyc.org/pdf/3967/396746694005.pdf

Kafi, A.; Daneshian, B. y Rostamy-Malkhalifeh, M. (2020) "Pronóstico del intervalo de confianza en la eficiencia de las unidades de toma de decisiones en el análisis envolvente de datos" Nexo Revista Científica, vol. 33, no. 2, pp. 431-445. https://dialnet.unirioja.es/servlet/articulo?codigo=7852455

Favila Tello, A. (2019) "Eficiencia de la innovación en América Latina. Una aproximación a través del Análisis Envolvente de Datos" Análisis económico, vol. 34, no. 87, pp. 249-267. https://www.redalyc.org/journal/413/41362257011/html/

Golsefid, F. G.; Daneshian, B. y Rostamy-Malkhalifeh, M. (2020) "Ranking of units by corrected cross-efficiency method using optimal weights in the smallest interval" Nexo revista científica, vol. 33, no. 02, pp. 446-453. https://dialnet.unirioja.es/descarga/articulo/7852456.pdf

Trujillo, J. y Brito, A. (2009) "Jusepin Main Station Separation Facilities Upgrade by Means of Integrated Multiphase Solutions" in SPE Latin America and Caribbean Petroleum Engineering Conference. https://www.researchgate.net/publication/254529402_Jusepin_Main_Station_Separation_Facilities_Upgrade_by_Means_of_Integrated_Multiphase_Solutions

Corvaro, F.; Giacchetta, G.; Marchetti, B. y Recanati, M. (2017) "Reliability, Availability,Maintainability (RAM) study, on reciprocating compressors API 618". Petroleum, vol. 3, no. 2, pp. 266-272. https://www.sciencedirect.com/science/article/pii/S2405656116301523

OREDA (2015). "Offshore and Onshore Reliability Data Handbook", NTNU. http://www.dl.edi-info.ir/The%20Offshore%20and%20Onshore%20Reliability%20Data%20OREDA.pdf

Faris, M. H. (2021) "Developing a Total Productive Maintenance Framework with RAM (Reliability, Availability and Maintainability) Techniques in Gas Compression Plants" Doctoral dissertation Sudan University of Science and Technology, Jartum.

Faris, M. H.; Elhussein, E., Osman Ali, H. y Yousif, A. (2019) "A Review of Applied Modern Condition Monitoring and Best Maintenance Engineering Practices in Reciprocating Gas Compression Plants" International Journal of Engineering Research and Technology, pp. 2983-2987. https://www.researchgate.net/publication/349522062_A_Review_of_Applied_Modern_Condition_Monitoring_and_Best_Maintenance_Engineering_Practices_in_Reciprocating_Gas_Compression_Plants

Blanco-Canto, M.; Bares-López, L. y Hrynevych, O. (2019) "Análisis de la eficiencia global de las 50 mejores universidades del mundo" Espacios, vol. 40, no. 9, pp. 30-48. http://ww.w.revistaespacios.com/a19v40n09/a19v40n09p30.pdf

Stefanović-Marinović, J.; Troha, S. y Milovančević, M. (2017) "An application of multicriteria optimization to the two-carrier two-speed planetary gear trains" Facta Universitatis, Series: Mechanical Engineering, vol. 15, no. 1, p. 85–95. https://www.researchgate.net/publication/316250507_An_application_of_multicriteria_optimization_to_the_two-carrier_two-speed_planetary_gear_trains

Starčević, S.; Bojović, N.; Junevičius, R. y Skrickij, V. (2019) "Analytical hierarchy process method and data envelopment analysis application in terrain vehicle selection" Transport, vol. 34, no. 5, pp. 600-616. https://journals.vilniustech.lt/index.php/Transport/article/view/11710

Velásquez, A. (2022) "Confiabilidad operacional en plantas compresoras de gas" Tesis de Maestría. Universidad de Oriente, Maturín.

Santos-Navarro, G.; Wong-González, P. y Martínez-Martínez, A. (2019) "Medición de la eficiencia técnica de la industria automotriz mediante el Análisis Envolvente de Datos" Economía, sociedad y territorio, vol. 19, no. 60, pp. 173-201. https://www.redalyc.org/journal/111/11162787007/html/

Lai, P. (2013) "A study on the relationship between airport privatization and airport efficiency. An Application of using AHP/DEA Methods " Tesis Doctoral para optar al Titulo de Doctor en Filosofía. Cardiff University. https://orca.cardiff.ac.uk/id/eprint/46617/1/2013%20Lai%20Po-Lin.pdf

Avkiran, N. K. (2006) "Productivity analysis in the service sector with data envelopment analysis", Brisbane, Australia: The University of Queensland. https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2627576

Molina-Villacís, C. J.; Romero-Villagrán, J. L. y Cevallos-Figueroa, N. G. (2020) "Consecuencias económicas del Covid 19 sobre el aparato productivo" Polo del conocimiento, vol. 5, no. 9, pp. 46-54. https://dialnet.unirioja.es/descarga/articulo/7554421.pdf

Diago-Diago, M. P. (2021) "Violación de derechos humanos en las cadenas de suministro en tiempos de pandemia" Revista Española de Derecho Internacional, vol. 73, no. 1, pp. 337-344. https://dialnet.unirioja.es/servlet/articulo?codigo=7806734

Olis Barreto, I. M., Reyes, G. E., Martin-Fiorino, V., y Villalobos-Antúnez, J. V. (2021). "Crisis empresarial, factores que influyen y alteran la gestión de las empresas en Colombia". Revista de ciencias sociales, 27(4), 93-112.," Revista de Ciencias Sociales, vol. 27, no. 4, pp. 93-112. https://www.redalyc.org/journal/280/28069360008/html/

Barabady, A.; Nouri, A.; Ataei, M. y Einian, V. (2017) "Spare part requirement prediction under different maintenance strategies" International Journal of Mining, vol. 33, no. 3, pp. 1-14. https://www.researchgate.net/publication/319870044_Spare_part_requirement_prediction_under_different_maintenance_strategies

Amendola, L. (2003) "Indicadores de confiabilidad propulsores en la gestión del mantenimiento", Valencia- España: Departamento de Proyectos de Ingeniería, Universidad Politécnica de Valencia. https://mantenimientoplanificado.com/Articulos%20gesti%C3%B3n%20mantenimiento_archivos/indicadores%20confiabilidad%20amendola.pdf

Melo-González, R.; Lara-Hernández, C. y Jacobo-Gordillo, F. (2009) "Estimación de la confiabilidad-disponibilidad-mantenibilidad mediante una simulación tipo Monte Carlo de un sistema de compresión de gas amargo durante la etapa de ingeniería" iencia Tecnol. Ed. Ciencia (IMIQ) Ed.vol. 14 (IMIQ)n, vol. 24, no. 2, pp. 93-104. https://www.redalyc.org/pdf/482/48213841002.pdf

Tobe, A. Y.; Widhiyanuriyawan, D. y Yuliati, L. (2018) "The integration of Overall Equipment Effectiveness (OEE) method and lean manufacturing concept to improve production performance (Case study: Fertilizer producer)" JEMIS (Journal of Engineering & Management in Industrial System), vol. 5, no. 2, pp. 102-108. https://www.researchgate.net/publication/324817539_THE_INTEGRATION_OF_OVERALL_EQUIPMENT_EFFECTIVENESS_OEE_METHOD_AND_LEAN_MANUFACTURING_CONCEPT_TO_IMPROVE_PRODUCTION_PERFORMANCE_CASE_STUDY_FERTILIZER_PRODUCER

Published

How to Cite

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The opinions expressed by the authors do not necessarily reflect the position of the publisher of the publication or of UCLA. The total or partial reproduction of the texts published here is authorized, as long as the complete source and the electronic address of this journal are cited.

The authors fully retain the rights to their works, giving the journal the right to be the first publication where the article is presented. The authors have the right to use their articles for any purpose as long as it is done for non-profit. Authors are recommended to disseminate their articles in the final version, after publication in this journal, in the electronic media of the institutions to which they are affiliated or personal digital media.