Visualization for the Conceptual Design of Multiphase Reactors. Case Study: Allyl Chloride Production

Keywords:

Conceptual design, Fixed bed reactor, Multiphase reactor, Allyl chloride, Direct chlorinationAbstract

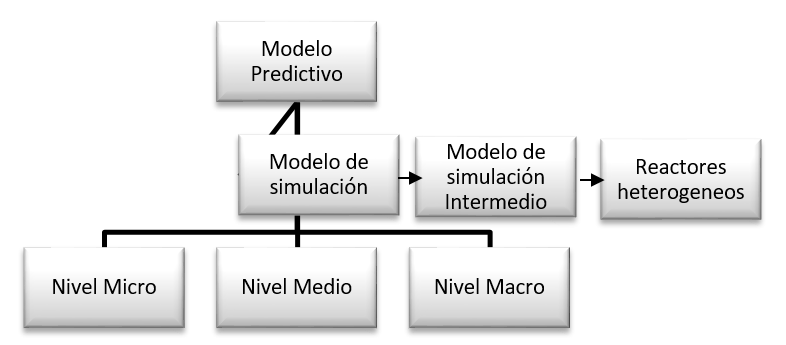

This paper shows the technical considerations to be taken into account for the conceptual design of an allyl chloride production reactor based on the methodology proposed by Krishna and Sie (1994), which consists of three levels: a) catalyst design, b) dispersion strategy of the reactant and energy and c) selection of the hydrodynamic flow regime. When selecting the configuration of a reactor, it is desired that it complies with a "Wish List", which refers to all the needs or requirements, such as maximum conversion and selectivity, easy operation, lower capital and operating costs, which are needed to achieve the best possible design of the equipment. Following the guidelines of the methodology, to begin with, the design of the catalyst was proposed, in this sense an extruded cylindrical morphology of CuCl2 eggshell type was selected. Once the catalyst design was established and, based on this, the injection of the feed to the system in stages was considered, with the purpose of maintaining a controlled chlorine concentration throughout the reactor, thus avoiding the formation of 2-3 dichloropropene, which is an undesired product. As a final instance, the hydrodynamic flow regime of the reactive system for the production of allyl chloride via direct chlorination of propylene was determined, the decision was based on taking into account strategies I and II, where a fixed bed configuration with an axial flow arrangement was the most suitable for the catalytic process. Likewise, it was considered to work in a non-adiabatic operating condition in a multitubular reactor (tube and shell), since there will be a heat transfer with the external medium (coolant).

Downloads

References

Bracho, N. (2011). Evaluación de tamices moleculares en la purificación de propileno utilizado en la producción de polipropileno. Recuperado el 27 de noviembre de 2023: https://dialnet.unirioja.es/servlet/articulo?codigo=3640202

Catalizadadores, cinética y lecho fijo. (s.f.). [Archivo PDF de la Universidad Politécnica de Madrid]. Recuperado el 26 de abril de 2025, de https://moodle.upm.es/en-abierto/pluginfile.php/866/mod_label/intro/cap5.pdf

Donald, E. (1960). Preparation of Allyl chloride. (United Stated patents. No. 2966525).

Ferrer, J. (2017). Fases de ingeniería de un proyecto. Recuperado 27 de noviembre del 2023: (https://es.linkedin.com/pulse/fases-de-ingenieria-un-proyecto-jos%C3%A9-ferrer

Gonzalez, D. (2019). Diseño de un reactor químico para la obtención del monocloruro de vinilo (VCM). Instituto Politécnico Nacional. Recuperado el 27 de noviembre del 2023: http://tesis.ipn.mx/handle/123456789/27936

Galiasso, Roberto, Riviere, Sheila, & Verruschi, Elisa. (2010). Diseño de un modelo en frío de un reactor de lecho fijo con empaques estructurados. Universidad, Ciencia y Tecnología, 14(57), 239-250. Recuperado el 27 de noviembre de 2023: https://ve.scielo.org/scielo.php?script=sci_arttext&pid=S1316-48212010000400004

Gonzalez, D. (2006). Diseño de un reactor químico para la obtención del monocloruro de vinilo (VCM)

Hornig, L., Lendle, W., Mau, G., Schmitz Heinz. (1970) Process for preparing allyl chloride and its monomethyl-substitution products. (United Stated patents. No. 3513207).

Hornig, L., Lendle, W., Mau, G., Schmitz Heinz. (1969). Process for preparing allyl chloride and its monomethyl-substitution products. (United Stated patents. No. 3545661).

Iborra, M., Tejero, J., Curnill, F. (2013). Reactor multifásicos. Universidad de Barcelona, p. 61.

Kneupper, C. & Saathoff, L. (1993). Chlorocarbons, -hydrocarbon, (allyl chloride). In: Kroschwitz, J.I. & Howe-Grant, M., eds, Kirk-Othmer Encyclopedia of Chemical Technology, 4th Ed., Vol. 6, New York, John Wiley, pp. 59–69.

Krahling, L. Key, J., Jakonson, G. (1985). “Allyl compounds” In Ullmann’s Encyclopedia of industrial chemistry. ed. W. Gerhartz. 425-445. 5th ed., Vol. A1. Weinheim: VCH Verlagsgesellschaft.

Krishna, R., Sie, S. (1994). Strategies for multiphase reactor selection. Chemical Engineering Science. Vol 49. No 24A. pp. 4029-4065.

Krishna, R., Sie, S. (1994). A sistems approach to multiphase reactor selection. Chemical Engineering Science. Vol 19. pp. 201-249.

Levenspiel, O. (2004). Ingeniería de las reacciones químicas. Limusa Wiley. 3ra Edición. pp.240

Marsella, A., Carmello, D., Fatutto, P. (2011). Catalizador y procedimiento de oxicloración que lo usa. (ES. Número de patente. 2226288T3). Recuperado el 27 de noviembre de 2023: https://patents.google.com/patent/ES2226288T3/es

Martínez, J. (1986). El Dominio Tecnológico Clave para el Desarrollo, conceptos e implicaciones técnicas, sociales y políticas, revista espacios, vol. 7 n°. 1. Recuperado el 11/03/2024: https://www.revistaespacios.com/a86v07n01/86070140.html

Minor, E. (s.f). Cinética química de reacciones heterogéneas. Recuperado el 27 de noviembre del 2023: https://reactorquimico.wordpress.com/unidad-iv/cinetica-quimica-de-reacciones-heterogeneas/

Mordor Intelligence. (2023). Cloruro de alilo análisis de tamaño y participación del mercado - tendencias de crecimiento y pronósticos (2023 - 2028). Recuperado el 27 de noviembre del 2023: https://www.mordorintelligence.com/es/industry-reports/allyl-chloride-market

Porter, L., Rust, F. (1956). “Pyrolisis of Allyl Chloride”. Journal of American Chemical Society. 78:5571-5573.

Potapov, A., Rafikov, S. (1987). Some mechanisms of catalytic direct and oxidative chlorination of propylene. Organic Chemistry. Plenum Publishing Corporation. P. 2252.

Sazuki, Y., Takenoue, A., Kojima, Hideo (1972) Oxychlorination process. (United Stated patents. No. 3699178).

Turton, R., Bailie, R., Whiting, W., Shaeiwitz, A. (2009). Analysis, Synthesis, and design of chemical Processes.

Verruschi, E. (2011). Optimización de reactores químicos. Editorial académica española. pp. 59-71.

Yabroff, D., Anderson, J. (1951). “A new chemical industry based on allyl chloride”. In world petroleum congress III - Section V in, 22-30.

Published

How to Cite

Issue

Section

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

The opinions expressed by the authors do not necessarily reflect the position of the publisher of the publication or of UCLA. The total or partial reproduction of the texts published here is authorized, as long as the complete source and the electronic address of this journal are cited.

The authors fully retain the rights to their works, giving the journal the right to be the first publication where the article is presented. The authors have the right to use their articles for any purpose as long as it is done for non-profit. Authors are recommended to disseminate their articles in the final version, after publication in this journal, in the electronic media of the institutions to which they are affiliated or personal digital media.